Spot weld bonding repair is a specialized automotive restoration technique that uses adhesive to merge metal surfaces, restoring structural integrity and providing durable, aesthetically pleasing results for weakened or detached spot welds. This method offers unparalleled strength, minimizes corrosion, reduces material waste, and has faster drying times compared to traditional methods, making it an ideal choice for professionals in the collision repair industry. To achieve optimal results, follow best practices including thorough surface preparation, precise alignment, controlled heat application, and expertise from auto body shops using state-of-the-art equipment.

Spot weld bonding repair has emerged as a game-changer in collision repair, offering enhanced strength and precision. This article delves into the world of spot weld bonding techniques, exploring its benefits and best practices. By understanding this advanced repair method, professionals can ensure robust and lasting results, revitalizing vehicles with optimal structural integrity. Discover how spot weld bonding repair strengthens collisions fixes, providing a superior alternative for auto body shops.

- Understanding Spot Weld Bonding Repair Techniques

- Benefits of Using Spot Weld Bonding in Collision Repairs

- Best Practices for Effective Spot Weld Bonding Repair

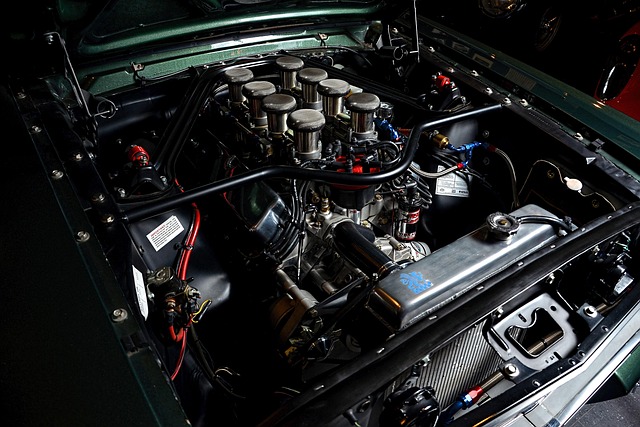

Understanding Spot Weld Bonding Repair Techniques

Spot weld bonding repair is a highly specialized technique used to reinforce and restore structural integrity in automotive body work. It involves precisely applying adhesive to join two or more metal surfaces, creating a strong and durable bond. This method is particularly effective for car damage repair, especially in cases where spot welds have become weakened or detached over time.

Automotive repair services often rely on this technique as it offers a precise and efficient solution. By using modern adhesives and specialized equipment, technicians can ensure the repaired area matches the original strength and stability of the vehicle’s body. This is crucial when aiming to provide high-quality car damage repairs that are both long-lasting and aesthetically pleasing.

Benefits of Using Spot Weld Bonding in Collision Repairs

Spot weld bonding repair has emerged as a game-changer in the collision repair industry, offering numerous benefits that traditional methods can’t match. By utilizing this advanced technique, automotive restoration experts can achieve exceptional strength and durability in repairing car damage. Spot weld bonding involves precisely applying adhesive to specific points (or ‘spots’) on the damaged area, creating a robust bond that effectively seals the gap left by dent repair or other modifications.

This method provides several advantages over conventional repairs. It ensures stronger hold, minimizing the risk of future corrosion and structural weakness. Moreover, spot weld bonding is less invasive, preserving more of the original vehicle integrity. This precision approach also results in faster drying times and reduced material waste, contributing to a more efficient automotive restoration process.

Best Practices for Effective Spot Weld Bonding Repair

To achieve optimal results with spot weld bonding repair, several best practices should be followed. Firstly, ensure proper surface preparation before beginning the repair process. This includes cleaning the affected area, removing any debris or rust, and ensuring the metal is free from contaminants. The use of specialized cleaning solutions and abrasives can help achieve a smooth, clean surface that promotes better adhesion for spot weld bonding.

Secondly, precise alignment is crucial during the welding process. Accurate positioning of the repair panel or component in relation to the existing body shop services ensures a seamless fusion. Proper techniques, including controlled heat application and appropriate cooling times, should be employed to strengthen the bond between the damaged area and the repair piece. Utilizing auto body shop expertise and state-of-the-art equipment can significantly enhance the precision and effectiveness of spot weld bonding repairs, ultimately improving the overall quality of car paint services.

Spot weld bonding repair has emerged as a game-changer in the collision repair industry, offering enhanced strength and precision. By understanding the techniques, leveraging its benefits, and adhering to best practices, professionals can achieve robust repairs that match or exceed vehicle manufacturers’ standards. Incorporating spot weld bonding into collision repair processes not only strengthens structural integrity but also ensures long-lasting results, ultimately elevating the quality of automotive service provided.